Achieve Superior Product Separation With Advanced Dirt Screens for Recycling Plants

In the ever-evolving globe of recycling plants, accomplishing premium material separation is vital to maximizing effectiveness and success. Get in advanced dirt displays, a technology that holds the pledge of revolutionizing the way waste is processed. These advanced displays are made to effectively different dust and various other contaminants from recyclable products, making certain a greater quality outcome. But exactly how do they work? And what are the key advantages of including these displays into recycling plant procedures? In this discussion, we will certainly discover the responses to these inquiries and dive into the elements to think about when selecting dirt displays, in addition to their execution and upkeep. Prepare to reveal the keys behind achieving remarkable material separation and remain tuned for the important insights that exist ahead.

The Importance of Advanced Dust Screens

The importance of sophisticated dust displays in recycling plants can not be overemphasized as they play an essential function in dividing and eliminating contaminants from recyclable products. These screens are especially designed to efficiently and successfully remove dirt, particles, and various other unwanted products from the reusing process, ensuring that just tidy and top notch recyclables are refined even more.

One of the key factors why advanced dust screens are vital is that they assist boost the overall quality of recyclable products. By eliminating contaminants such as dirt, rocks, and other non-recyclable items, the displays ensure that the final recycled items are of greater pureness and fulfill the needed sector criteria. This not only boosts the worth of the recycled materials however likewise enhances their bankability.

Moreover, advanced dirt screens help to stop damage to recycling devices. Pollutants like rocks or steel things can create significant damage to machinery such as conveyors, crushers, and shredders, causing pricey fixings and downtime. By effectively separating these contaminants at the onset of the reusing process, dust displays aid to extend the lifespan of the devices and reduce upkeep costs.

In enhancement to improving material top quality and safeguarding devices, advanced dust screens also contribute to a safer working atmosphere - dirt screens for sale. By getting rid of sharp items, dangerous products, or possibly hazardous compounds, these displays lower the danger of injuries or accidents to employees, ensuring a much safer office for everyone included

Just How Advanced Dust Screens Job

Advanced dirt displays in reusing plants feature by utilizing specific mechanisms to separate and eliminate contaminants from recyclable products, making certain that top quality and only clean products continue via the recycling procedure. These screens are developed to deal with large volumes of mixed waste and properly eliminate undesirable substances, such as dust, particles, and smaller sized particles, from the recyclable materials.

The primary step in the procedure involves the feeding of combined waste products onto the dust display. The display is equipped with a collection of openings or perforations that allow smaller sized fragments to travel through while maintaining bigger and better products. As the waste products move along the display, a mix of mechanical resonances and gravitational pressures aids to divide the contaminants from the recyclables.

To optimize performance, advanced dirt screens utilize numerous technologies, such as oscillating or shaking screens, to boost the separation procedure (dirt screens for sale). These displays can be fine-tuned to accomplish the desired separation dimension, ensuring that only the cleanest and most important materials continue with the reusing process

Furthermore, some sophisticated dust screens utilize air jets or suction systems to better improve the splitting up process. These systems blow or vacuum away lighter contaminants, such as paper or plastic movie, leaving the larger and more beneficial recyclable materials.

Secret Advantages of Making Use Of Advanced Dirt Screens

Utilizing innovative dust screens in recycling plants uses countless benefits in terms of performance, efficiency, and total top quality of the recycling process. These sophisticated screens are designed to separate dust, that site debris, and other undesirable products from the recyclable products, resulting in a purer end item.

One more benefit is the boosted effectiveness of the recycling process. Advanced dust displays visit the website are made to precisely and effectively separate recyclable products from contaminants, making sure a better end product. This aids to satisfy stringent recycling criteria and enables the production of cleaner and purer products that can be made use of in different sectors.

In addition to efficiency and performance, using sophisticated dust screens likewise contributes to the total top quality of the reusing procedure. By eliminating dirt and debris, the screens help to minimize the risk of contamination, making sure that the recycled products are of a greater requirement. This not only enhances the value and marketability of the recycled materials but additionally advertises sustainability by reducing the need for virgin resources.

Variables to Consider When Picking Dirt Screens

When selecting dust screens for recycling plants, it is vital to think about numerous factors to make sure optimal performance and effectiveness. Among the first aspects to think about is the size of the display. The dimension of the dust screen will figure out the size of the particles that can go through, so it is crucial to select a display dimension that is ideal for the particular materials being refined.

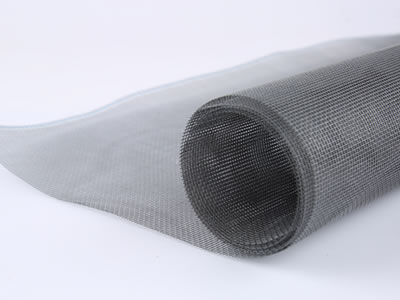

An additional important element to think about is the product of the display. Various products have different levels of sturdiness and resistance to tear and wear. It is vital to choose a display product that can hold up against the harsh conditions of the recycling plant and maintain its efficiency gradually.

Furthermore, the style and arrangement of the dust display need to be taken into consideration. The display needs to be designed to take full advantage of the splitting up of different materials and avoid blocking or blockages. The spacing between the wires or openings on the screen must be thoroughly picked to attain the preferred separation efficiency.

Furthermore, the maintenance needs of the dust display ought to also be considered. Screens that are very easy to tidy and preserve will help to decrease downtime and make certain continual operation of the recycling plant.

Implementation and Upkeep of Dust Screens

To successfully carry out and maintain dirt screens in reusing plants, cautious consideration must be offered to their setup and ongoing maintenance. Appropriate installation is crucial to make certain the screens function ideally and supply exceptional product separation. Throughout setup, it is necessary to place the screens in such a way that enables for easy accessibility for maintenance and cleansing. This may involve critical placement of accessibility points and using proper assistance structures.

Normal maintenance is important to keep dust displays in optimum problem and optimize their performance. This consists of regular inspections to determine any type of indications of wear or damages, find more such as splits or openings in the displays.

Cleaning up the displays regularly is also essential to stop obstructions and make certain continual procedure. This can be done making use of numerous approaches such as air or water blasts, depending upon the sort of display and the degree of dirt accumulation. When cleansing the displays to stay clear of causing any kind of damages., it is vital to comply with producer guidelines and referrals.

Final Thought

To conclude, using innovative dust displays in recycling plants is important for attaining superior material separation. These screens successfully eliminate dust and various other impurities, ensuring the production of high-quality recycled materials. The crucial advantages of using advanced dirt screens include increased efficiency, improved product quality, and reduced maintenance costs. When choosing dirt displays, variables such as display dimension and product must be thought about. Appropriate application and routine maintenance of these screens are vital for ideal performance.

These advanced screens are designed to divide dust, particles, and other unwanted products from the recyclable materials, resulting in a purer end product. Advanced dust screens are developed to accurately and efficiently different recyclable products from contaminants, guaranteeing a greater top quality end product. The dimension of the dirt screen will certainly determine the dimension of the bits that can pass through, so it is essential to pick a screen size that is appropriate for the specific products being processed.

In verdict, the usage of sophisticated dirt displays in recycling plants is critical for attaining exceptional product separation. When picking dirt displays, elements such as screen dimension and material should be considered.